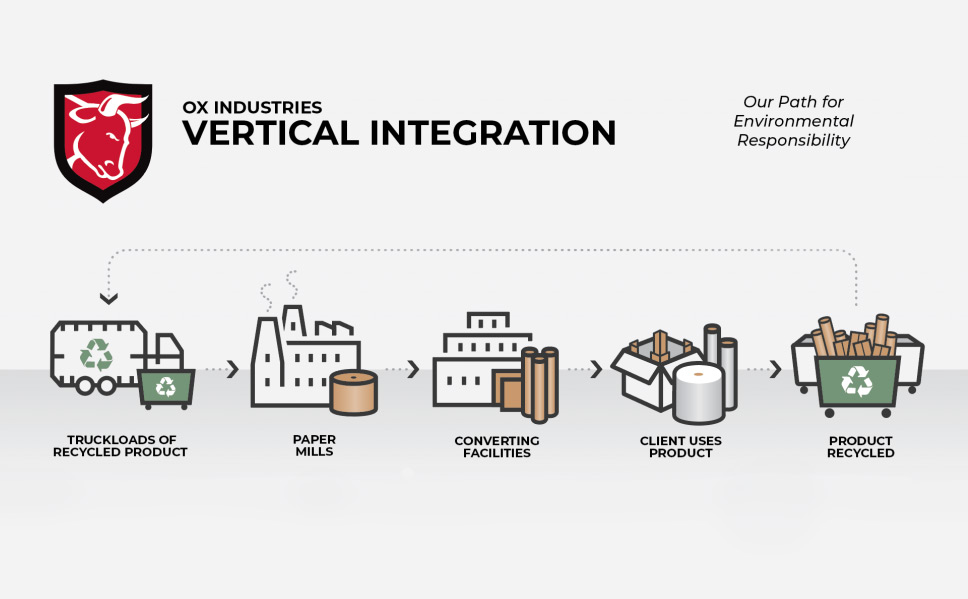

Vertical integration is a method of reducing costs, improving production efficiency, and decreasing the amount of product waste by gaining control of production and the supply chain from end to end. Through the years, it has proven to be an effective strategy for hundreds of mid-size and large companies. However, the net positive outcomes of vertical integration are not isolated to ultimately powering up a business’s bottom line. When a company has achieved vertical integration, the consumer of the product produced will feel the benefits in many ways.

Our approach to becoming vertically integrated is unique. The initial instinct to acquire control of our supply chain came from the desire to assure sustainable products and processes. When we opened our doors in 1996, we worked to produce the most environmentally sustainable product possible, using recycled material purchased from paper mills. We knew that if we wanted to make a positive impact on the environment while also maintaining the most efficient production lines and highest quality product we needed to be in control of our paper source. In 2007, with that goal in mind, we purchased Halltown Paper Mill founded in 1869 and became a 100% vertically integrated producer of recycled paperboard.

Vertical Integration Adds to Environmental Sustainability

Vertical integration has proven to be an equitable business decision, but more so, we have realized a decreased carbon footprint improving our viability as a sustainable business. We have added to our capacity to provide customers with the product knowledge they deserve, increasing our production efficiency while controlling costs as the market allows. Our vertical integration process continues to add strength to operations giving our customers even more reasons why they can continue to Count on Ox.